Air Tools

Air Tools

Air tools are lightweight, portable, easy-to-use, and can speed up work related to drilling, sanding, painting, or spray painting. They’re also of great use in remote locations that have little to no access to power.

24/7 Emergency Construction Service.

Request a Free Estimate

Air Vaccum

Air vacuum cleaners are compact and lightweight. These industrial vacuum cleaners works on compressed air and are capable of cleaning off water, oil and bottom sludge as well as dust and metal clippings. Their unique design permits the use of an ordinary pail or can with an outside diameter of 300mm to collect the dust and waste. Standard equipment includes a pail can, 2 meters of oil resistance hose, and an oil stopper which automatically stops suction when the receiver becomes full.

| IMPA number | Part number | Hose (oil resistant) | Air Consumption @ 5 kgf/cm2 | Vacuum (in water column) @ 5 kgf/cm2 | Suction Capacity @ 5 kgf/cm2 | Air Inlet | Weight |

| 59 07 22 | KLIN50 | 32 mm(dia) x 2 m | 500 ltr/min | 2600 mm | 1.8 m3 | 3/8″ BSPP | 5.83 Kg |

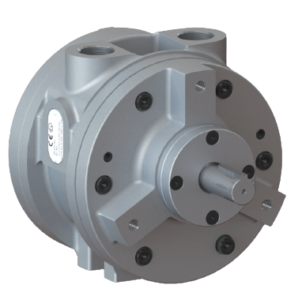

Air Motor

Air Motors are Stall proof, Self Cooling, have a High Power to weight ration, ATEX Explosion proof and Reversible – Thus making them the preferred choice for any of your application. Our air motors are versatile workhorses that can be used in a diverse range of applications. In many applications the inherent features of air motors make them more suitable over electric or hydraulic options.

Such compressed Air Motors are used for mixing, lifting and pulling applications in explosive zones.

Speed and torque can be varied by simple modulation of input air pressure and air volume. These air motors are suitable because of the many features that they exhibit.

For example these air motors are able to be loaded till stall point without damage. Air motors can also tackle variable loads and are capable to be operated in environments where electrical motors are hazardous. One more important feature of compressed air motors is their compact size as compared to electrical motors.

Air motors are also available as completely Lubrication free air motors and Stainless Steel air motors for use in hygienic applications

Part No | Power | Torque | Air Consumption | Weight | Operating Pressure | Max Allowable speed | REPAIR KIT |

1VM | Up to 0.35kW (0.45HP) | Up to 0.55 Nm (5 lbs-in) | 0 to 30m3/hr (0 to 22 cfm) | 0.9kgs (2lbs) | 1.4 to 7kg/cm2 (20 to 100PSI) | 7000 rpm (ATEX limit) | Kit No 8119701 |

2VM | upto 0.7kW (0.9HP) | upto 2 Nm (19 lbs-in) | 0 to 50m3/hr (0 to 30 cfm) | 3.25 kgs ( 7.15 lbs) | 1.4 to 7kg/cm2 (20 to 100PSI) | 4000 rpm (ATEX limit) | Kit No 8039701 |

4VM | upto 01.25 kW (1.7HP) | upto 4 Nm (35 lbs-in) | 0 to 120 m3/hr (0 to 72 cfm) | 3.8 kgs ( 8.3 lbs) | 1.4 to 7kg/cm2 (20 to 100PSI) | 3500 rpm (ATEX limit) | Kit No 8049701 |

6VM | upto 3 kW (4HP) | upto 6 Nm (53 lbs-in) | 0 to 240 m3/hr (0 to 140 cfm) | 7.5 kgs ( 16.5 lbs) | 1.4 to 7kg/cm2 (20 to 100PSI) | 3500 rpm (ATEX limit) | Kit No 8059701 |

8VM | upto 4 kW (5 HP) | upto 15 Nm (130 lbs-in) | 0 to 300 m3/hr (0 to 175 cfm) | 11 kgs ( 24.2 lbs) | 1.4 to 7kg/cm2 (20 to 100PSI) | 2500 rpm (ATEX limit) | Kit No 8069701 |

16VM | upto 7 kW (9.5 HP) | upto 35 Nm (294 lbs-in) | 0 to 470 m3/hr (0 to 270 cfm) | 32 kgs ( 70 lbs) | 1.4 to 7kg/cm2 (20 to 100PSI) | 2000 rpm (ATEX limit) | Kit No 8109701 |

Air chipping hammer

Pneumatic Chipping Hammers are used for billet chipping, general chipping and the removal of calking / weld flux, paint and rust in constricted

IMPA number | Part number | Type of Shank | Blows per | Piston Diameter | Air Inlet | Air hose |

59 03 61 | CH26R | Round | 2600 bpm | 19 mm | 1/4″ BSPP | 9.5 mm |

59 03 62 | CH23R | Round | 2300 bpm | 18 mm | 1/4″ BSPP | 9.5 mm |

Air Drill

Pneumatic Drills are ideal for light and medium drilling applications.

IMPA number | Part number | Drilling Capacity | Collect Chuck Size | Free Speed | Air Inlet | Air Hose |

59 03 41 | PD6PG | 6.5 mm | 6.5 mm | 2900 rpm | 1/4″ BSPP | 9.5 mm |

59 03 42 | PD10PG | 9.5 mm | 9.5 mm | 1400 rpm | 1/4″ BSPP | 9.5 mm |

59 03 43 | PD8PG | 8.0 mm | 8.0 mm | 1500 rpm | 1/4″ BSPP | 9.5 mm |

59 03 44 | PD13PG | 13.0 mm | 13.0 mm | 700 rpm | 1/4″ BSPP | 9.5 mm |

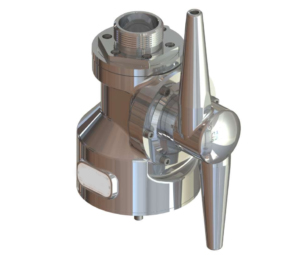

Rotary tank cleaning jets – TC 110J

These are twin nozzle tank washing machines. They have a Stainless Steel 316L construction combined with PEEK gears for durability and chemical resistivity. The two opposing nozzles continuously rotate in two axes and complete a complete cleaning cycle in 20 minutes

Suitable for use with various cleaning media including water, crude oil and cleaning chemicals, both hot and cold. Its easily repairable on site.

Property | Value |

Maximum Discharge | 27 m3/hr (450 litres/min) |

Maximum Jet Length | 31 meters (100 feet) |

Operating Pressure Range | 3 to 12 bar |

Machine Weight | 7 kgs (15.4 lbs) |

Temperature upto | 90 deg C (194 deg F) |

Cycle time | 20 mins (with std 8mm nozzle and 8 Bar supply pressure) |

Portable Thread detail | 1-1/2 inch BSP or 1-1/2 NPT (pl specify while ordering) |

Fixed Flange Detail (opt) | 5” OD X 3.88” PCD X 0.62” Bolt Hole Dia, (127mm, 98.5, 15.7mm resp) as ANSI B16.5 Class #150 |

Air ventilating Fan

Air Powered Ventilating Fans are compressed air driven ventilators that can be used with or without a duct in hazardous areas such as cooling tanks or hatches. They provide ventilation of gas, paint fumes and other hazardous fumes. Ducting tubes sold separately.

IMPA number | Part number | Casing Dia | Air Inlet Supply | Capacity | Water Consumption | RPM | Weight |

59 14 25 | PVF 300 | 300mm | 6 kg/cm2 | 3566 m3/hr | 24 – 58 m3/m | 3000 | 9 Kgs |

59 14 26 | PVF 400 | 400mm | 6 kg/cm2 | 8665 m3/hr | 24 – 58 m3/m | 3600 | 17 Kgs |

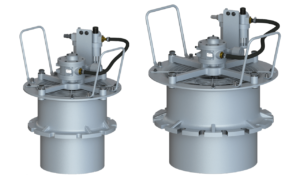

Air driven gas freeing fans

Air Driven Gas Freeing Fan are designed for ventilation of gases from large enclosed areas or other tank openings. They work effectively, providing penetration deep into the tank ensuring complete ventilation. Our fans are made of a non spark construction with a stainless steel 316 impeller and integral water motor. The components are manufactured from corrosion proof material.

IMPA number | Part number | Outlet Bore Dia | Max Air Flow | Air Pressure | Air Consumption | Air Hose (Inch) | Air Inlet & Outlet | Weight |

59 14 46 | PTF 300 | 300mm | 130 m3/m | 6.2 Bar (90 psi) | 40 m3/hr | ½” | ½” NPT | 32 Kgs |

59 14 47 | PTF 400 | 400mm | 210 m3/m | 6.2 Bar (90 psi) | 50 m3/hr | ½” | ½” NPT | 42 Kgs |

Air grinder

Pneumatic Angle Grinders are well suited for rugged production use. They are economically designed and kept as light as possible to reduce fatigue.

IMPA number | Part number | Wheel Size | Free Speed | Air Inlet | Air Hose | Weight |

50 03 01 | AG 4 | 100 x 6 x 15 mm | 13600 rpm | 1/4″ BSPP | 9.5 mm | 1.7 kgs |

50 03 02 | AG 7 | 180 x 6 x 25 mm | 7600 rpm | 3/8″ BSPP | 12.7 mm | 3.0 kgs |

Die grinder

Pneumatic Die Grinders are used either with tungsten carbide burrs or mounted points. They are compact & easy to handle air tools designed for, grinding small casting, removing wedding slag and sharpening & finishing wood, glass& plastic.

IMPA number | Part number | Collet Size | Free Speed | Air Inlet | Air Hose | Weight |

50 03 26 | LG25K | 6 mm | 25000 rpm | 1/4″ BSPP | 9.5 mm | 0.53 kgs |