Pneumatic Pumps

Pneumatic Pumps

Air operated diaphragm pumps have features like anti-stall, lube free and diaphragm options that give you a more practical and budget friendly alternative. Our sale in over 30 countries is testimony to the value for money that every AODD pump delivers.

Supported by strong no nonsense warranties and easy pricing on spares, AODD pumps are quickly gaining market share in many markets, as being found out by our happy distributors worldwide.

All AODD pumps are ATEX explosion proof and CE Certified. Our pumps are equivalent in performance to popular brands like Wilden and Graco.

24/7 Emergency Construction Service.

Request a Free Estimate

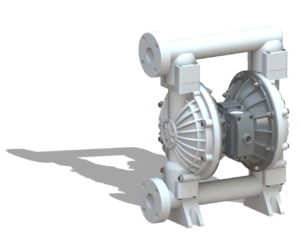

Aluminium AODD Pumps

Aluminum pumps main feature is their portability due to the light weight to pumping capacity. Ideal for pumping of water and water based fluids. Non aggressive fluids, oily fluids and fluids having low acidic or alkali concentrations are also well handled.

Aluminium constructed pumps are commonly combined with Neoprene, Nitrile, Santoprene, Hytrel, Viton or PTFE Elastomers. With these elastomers they are ideal for pumping of water and water-based fluids, non-aggressive fluids, oily fluids and fluids having low acidic or alkali concentrations

Aluminium Pumps offer a relatively low-cost solution to many pumping applications.

For this purpose, the main industries that choose Aluminium pumps are Paints, Marine, Mining, Ceramic and Wastewater/Pollution management.

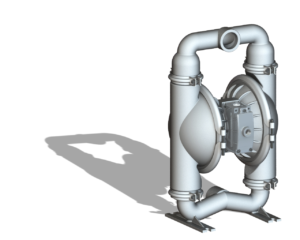

Stainless Steel AODD Pumps

Stainless Steel pumps are used where there is a demand for high pumping performance, combinations of both hot and corrosive fluids, both acidic and alkali. They are the ultimate choice for durable long life performance.

Samira offers some class leading diaphragm materials in combination with these pumps to tackle some of the most difficult pumping applications.

Stainless Steel constructed pumps are used in applications which demand high pumping performance, combinations of hot and corrosive fluids, both acidic and alkali. They are the ultimate choice for durable long life performance. These pumps are usually combined with highly capable and corrosion resistant diaphragms, mainly PTFE and often Viton and Santoprene. With these Elastomers they are ideal for pumping of fluids like benzyl diacetone, phosphoric acid, ferric sulphate, isopropyl chloride, transformer oils and many other similar fluids. Excellent choice when pumping highly aggressive fluids such as aromatic or chlorinated hydrocarbons, acids, caustics, ketone and acetones.

These pumps find wide applications across industries, some popular industries are Chemicals, Pharma, Food/Beverage and Electronic manufacturing.

Polypropylene AODD Pumps

Polypropylene pumps are a suitable low cost alternative to SS pumps especially where hot operability or rough outdoor environments are not present. Good for acids and alkalis.

Polypropylene pumps or PP pumps are lower in cost to Stainless Steel pumps, and can be a suitable alternative in a majority of the applications. In applications which need high operational temperatures or outdoor rough environments, Stainless Steel is still preferred. With these elastomers they are ideal for pumping of fluids like benzyl, diacetone, phosphoric acid, ferric sulphate, isopropyl chloride, transformer oils and many other similar fluids.

These pumps find wide applications across industries, some popular industries are Chemicals, Pharma and Electronic manufacturing.

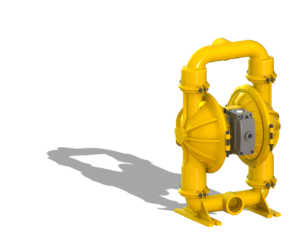

Ductile Iron AODD Pumps

For the toughest outdoor and underground duty, Ductile iron pumps are ideal. All pumps shown here have Mining ATEX explosion proof ratings. Application include removal of underground water / drift water from mine sites, transfer of muck, slime and slurry, oil transfer and general utility use.

Our Cast Iron pumps are constructed out of a special tough spheroidal graphite Iron, to withstand the toughest duty outdoors. They are primarily designed for use in underground mining atmospheres. All pumps have a Mining ATEX approval.

They employ a special version of the air valve system which contains no aluminium, so as to be compatible with mining regulations. All diaphragm options are available, including the popular BunaN and Hytrel versions.

Skid mounting, inlet strainer bases and frames are all available.Applications include removal of underground water / drift water from mine sites, transfer of muck, slime and slurry and oil transfer and utility use.

Pneumatic Centrifugal Pump

Pneumatic Centrifugal Pumps are used to empty ballast tanks, bilge wells, etc. Often used for draining cargo holds during and after the washing procedure. Our Centrifugal pumps have a small cross-section and hence can be lowered into areas having small access hatches. Especially preferred where an eclectic spark may risk ignition or explosion. Required air pressure is 059 MPa (6kgf/cm2).

IMPA number | Part number | Head Capacity | Discharge Capacity | Air Consumption | Fluid Outlet | Air hose | Weight |

59 16 35 / 59 16 36 | SP 10 | 27 meter | 48 m3/hr | 2.7 m3/m | 2” Hose | ¾” NPT | 22 Kgs |

59 16 37 | SP 25 | 24 meter | 60 m3/hr | 3.5 m3/m | 2 ½” Hose | ¾” NPT | 32 Kgs |